Affordable and Eco-Friendly Transformer Maintenance With Regenerated Oil

The assimilation of regenerated oil in transformer upkeep presents a compelling technique for companies seeking to boost both cost-efficiency and eco-friendliness. By utilizing oil that keeps performance criteria comparable to virgin options, businesses can significantly decrease functional costs while all at once lessening their environmental influence. This strategy not only addresses the financial concerns associated with waste disposal and frequent oil modifications but also contributes to broader sustainability initiatives. The ramifications of this shift expand beyond prompt benefits; recognizing the full extent of its benefits calls for a better assessment of the methods and principles involved.

Recognizing Regenerated Oil

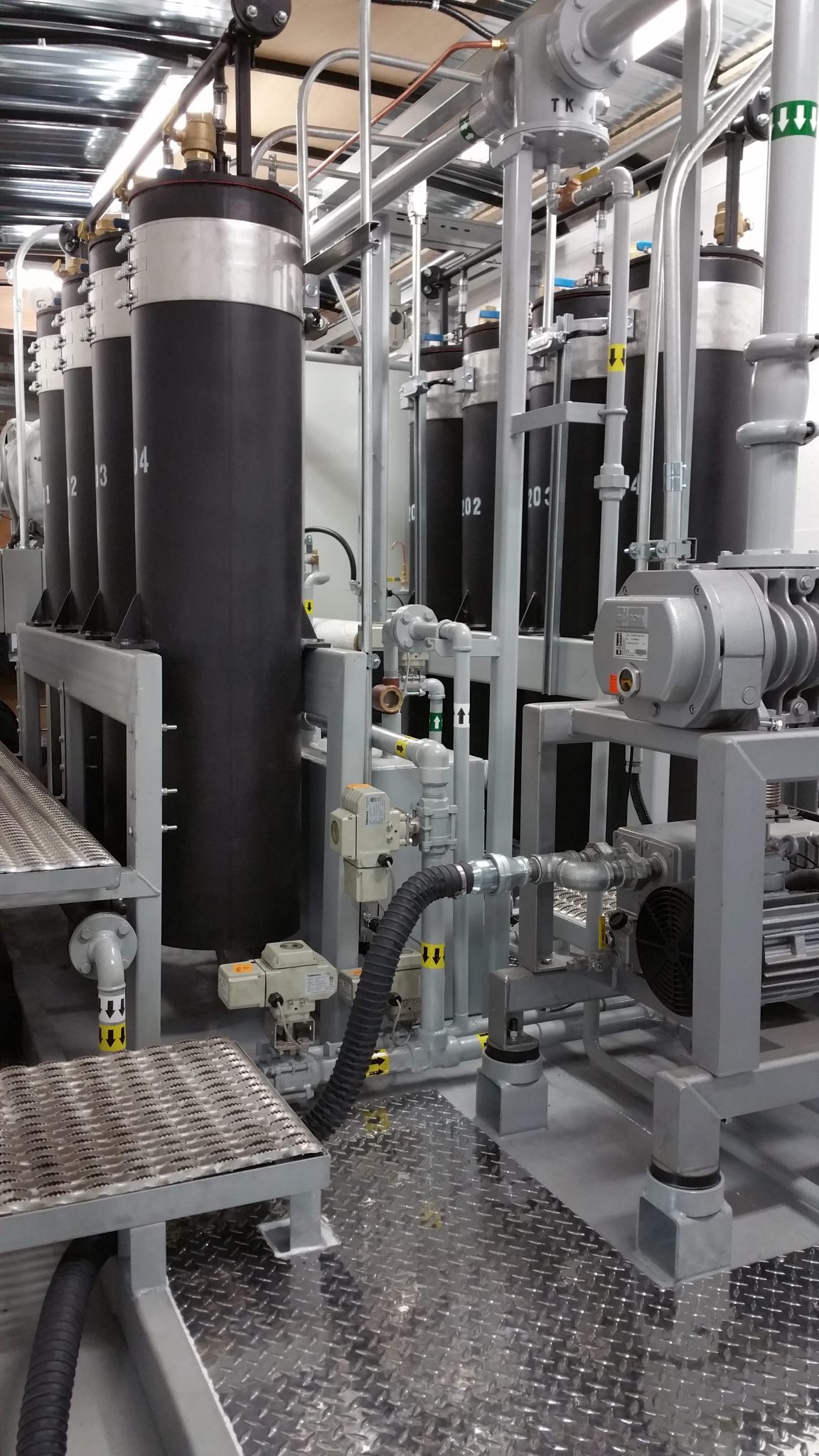

Regrowed oil, typically described as re-refined oil, is a critical element in the maintenance of transformers, providing both environmental and financial advantages. This oil is obtained from used mineral oils that have undertaken a detailed purification procedure, properly removing contaminants and restoring the oil to a top quality similar to virgin oil. The regrowth process typically entails several phases, including physical splitting up, chemical therapy, and purification, making sure that impurities such as sludge, water, and hefty metals are eliminated.

The usage of regrowed oil in transformers is vital for enhancing performance and extending tools life-span. High-grade re-refined oil maintains its dielectric properties, guaranteeing efficient insulation and protecting against electric breakdowns. Additionally, it possesses excellent thermal conductivity, which assists in managing the operational temperature levels of transformers, ultimately enhancing their dependability and effectiveness.

Furthermore, taking on restored oil not just sustains economical maintenance strategies however also lowers the requirement for new oil production, thus conserving natural deposits. Transitioning to re-refined oil is a smart selection for companies aiming to maintain high operational standards while simultaneously managing spending plan restraints. Understanding the properties and benefits of regrowed oil is critical for educated decision-making in transformer upkeep methods.

Ecological Benefits

Using regenerated oil in transformer maintenance provides significant environmental advantages that add to lasting methods within the power sector. Among the key benefits is the decrease of waste oil disposal, as regenerated oil is originated from the recycling of utilized transformer oil, dramatically reducing the quantity of contaminated materials generated. This procedure aids mitigate the environmental threats associated with improper disposal techniques, which can cause soil and water contamination.

Furthermore, the regrowth procedure preserves natural deposits by reducing the need for brand-new base oil manufacturing - Regenerated Transformer Oil. This conservation effort not just lowers the extraction effect on ecosystems yet additionally reduces the carbon footprint connected with oil manufacturing. By taking on restored oil, companies can advance their commitment to ecological stewardship and straighten with worldwide sustainability objectives

Furthermore, making use of regenerated oil improves the overall performance of transformers, bring about decreased energy losses and lower greenhouse gas emissions. As the power industry increasingly encounters stress to reduce its environmental impact, embracing regrowed oil represents a proactive technique to attaining both functional and environmental objectives. In recap, the ecological benefits of utilizing regenerated oil are diverse, promoting a healthier planet while supporting the look at more info power market's transition in the direction of sustainability.

Cost Cost Savings and Efficiency

Utilizing regenerated oil in transformer upkeep can bring about significant cost savings and improved operational performance for energy business. Restored oil, visit homepage generated through sophisticated filtration processes, uses comparable efficiency to new oil at a fraction of the cost. By recycling oil that would otherwise be discarded, companies can decrease their acquiring expenses while decreasing waste disposal prices.

Additionally, the long term life cycle of restored oil translates to minimized regularity of oil adjustments, resulting in lower labor expenses and reduced downtime for maintenance activities. Transformer Oil Regeneration Process. This not only improves operational effectiveness but also enables an extra structured maintenance schedule, making it possible for firms to allot sources more properly

In addition, using regenerated oil can bring about lower insurance costs because of its eco-friendly account. As power companies deal with enhancing scrutiny regarding their environmental effect, taking on sustainable methods such as using restored oil can boost their credibility and possibly bring in financial investment.

Ultimately, the combination of regrowed oil right into transformer upkeep practices presents a strategic chance for power business to accomplish substantial price financial savings while promoting operational effectiveness, consequently straightening financial efficiency with environmental obligation.

Comparison With Traditional Oils

While conventional oils have actually long been the criterion in transformer upkeep, a comprehensive comparison exposes that regenerated oils supply a number of advantages that enhance performance and sustainability. Traditional mineral oils, while efficient, typically pose environmental dangers, such as contamination and disposal problems. In comparison, regenerated oils are stemmed from recycled products, considerably decreasing their ecological impact.

Among the crucial differentiators is the chemical stability of regenerated oils. They commonly display exceptional oxidative stability, which converts to longer life span and minimized frequency of oil modifications. This particular not only improves transformer performance but additionally lessens investigate this site downtime and upkeep costs. Furthermore, regenerated oils often have reduced levels of dangerous ingredients, making them a safer option for both devices and the setting.

This top quality is critical in maintaining transformer capability under differing operational conditions. Generally, the advantages of regenerated oils over traditional oils highlight their possible to change transformer upkeep techniques, offering a much more liable and efficient alternative.

Implementation in Maintenance Practices

As soon as the evaluation is full, a customized strategy for transitioning to restored oil needs to be created, thinking about variables such as compatibility with existing products and functional conditions. Educating for upkeep personnel is important, as they have to comprehend the special residential properties of regenerated oils and just how to handle their application properly.

Carrying out a strenuous monitoring program will promote the assessment of efficiency metrics post-implementation, ensuring the regenerated oil satisfies the called for operational standards. Regenerated Transformer Oil. Furthermore, developing a normal upkeep schedule will assist in determining prospective problems early and permit timely corrective activities

Conclusion

Finally, the adoption of regenerated oil for transformer maintenance presents a sensible service that straightens economic benefits with environmental sustainability. By lowering costs connected with oil modifications and garbage disposal, while simultaneously expanding the life expectancy of devices, organizations can enhance functional performance. The change to restored oil not only mitigates environmental influences but additionally supports broader sustainability purposes, making it a sensible selection for modern-day maintenance methods in the energy field.

Regrowed oil, often referred to as re-refined oil, is an essential element in the maintenance of transformers, offering both environmental and economic advantages. This oil is derived from used mineral oils that have undergone a detailed filtration process, efficiently eliminating impurities and recovering the oil to a quality comparable to virgin oil.In addition, taking on regenerated oil not only supports economical maintenance methods but likewise decreases the need for brand-new oil manufacturing, thereby saving natural sources. One of the primary benefits is the decrease of waste oil disposal, as regenerated oil is obtained from the recycling of made use of transformer oil, substantially decreasing the quantity of harmful waste produced. Regrowed oil, generated with advanced filtration processes, supplies comparable performance to brand-new oil at a portion of the price.

Comments on “Efficiency Enhances With the Transformer Oil Regeneration Process”